Hebei Oulite Wire Mesh Machinery Co., Ltd. is an enterprise which

is specialized in researching and developping, designing,

manufacturing, sales and service of wire mesh machinery and

equipment. Since its establishment, it has been devoted to the

service tenet of "one time cooperation and lifetime after-sales".

Our company's main products are

Galvanized wire production line, the production line is mainly used

for the production of galvanized steel wire and galvanized iron

wire, the product is widely used in the production of various wire

mesh and construction fields. Our company has a professional design

team to customize equipment solutions according to the customer's

work site. And we have engineer is responsible for installation and

commissioning until the equipment is used normally.

Chain link fence machine is divided into single wire chain link

fence machine and double wire chain link fence machine. It adopts

servo motor, PLC control system, has performance of high

positioning accuracy, high output, labor saving, low noise, and can

run continuously for 24 hours.

The dipping equipment includes roll-mesh dipping and panel mesh

dipping. The equipment uses high-temperature heating to wrap the

PVC powder on the wire mesh product. The processed products are

more beautiful and durable. Heating methods include electric

heating and natural gas heating.

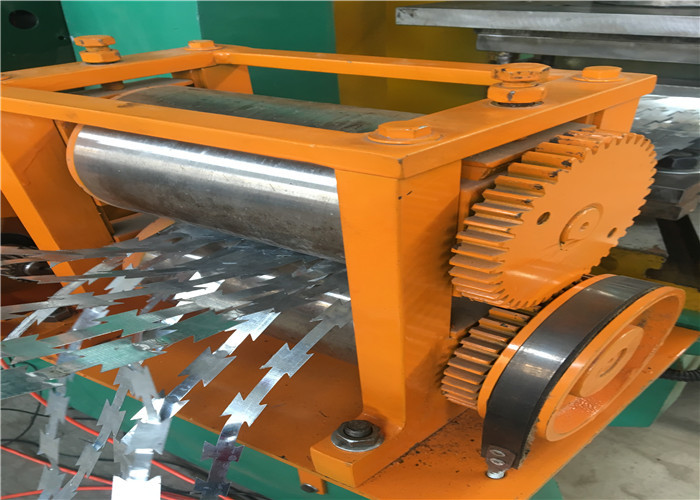

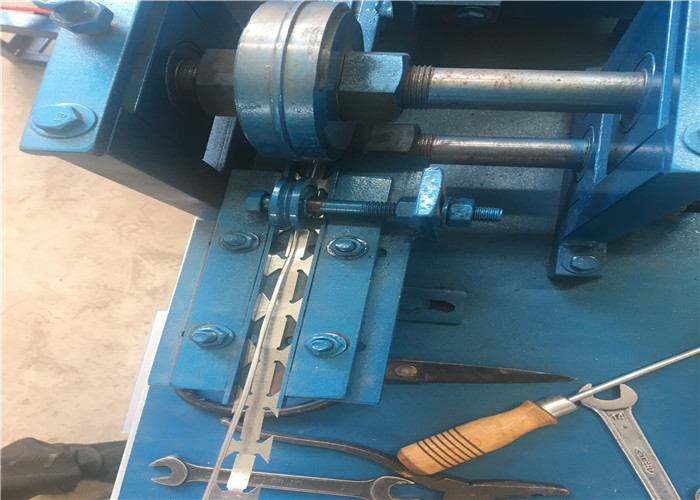

At the same time, the wire mesh welding machine, welded wire mesh

machine, wire drawing machine, barbed wire machine, razor barbed

wire machine and crimped wire mesh machine produced by our company

are well received by our customers.

We have a professional production team and after-sales service

team, constantly develop and update equipment to make the machine

more efficient and smarter, makes us always stay at the leading

level in the industry. Professional customer service maintains

online communication 24 hours a day to solve problems for customers

in a timely manner.

To provide users with high-quality products and the most complete

service is the mission and pursuit of all employees of our company.

Looking forward to hearing from you soon